Precision Filter Element

Precision Filter Element

Advantages:

- The filter housing is made of aluminum alloy by die-casting and has a compact structure to ensure safe use.

- All housings are cleaned, degreased, and specially anti-corrosion treated before spraying to improve durability and applied to offshore platform operations.

- The precise threaded interface makes installation and maintenance more accessible and more convenient.

- All housings tested under working pressure 32bar for 96 hours, and the maximum burst pressure is 105bar.

- Under the working condition of 1.5-80 ºC and pressure 16 bar, the body is guaranteed 15 years, and the service life of the Filter Element is 6000-8000 hours.

details

Quality Assurance

Anka air filter element has a large capacity to contain dust, and the service life of filter element can reach 6000-8000 hours under the general pressure difference of 0.17-0.25kg/cm and not more than 0.5kg/cm.

High Quality

Using high-quality Sodium borosilicate glass fiber, durable and reliable.

In precise filters, element life is determined by pressure drop. In absorption filters, element life is governed by saturation. It is worthwhile changing the filter elements at prescribed periods whether or not the pressure drop indicates it to be due. Elements should be changed at least once a year.

Technical Specification

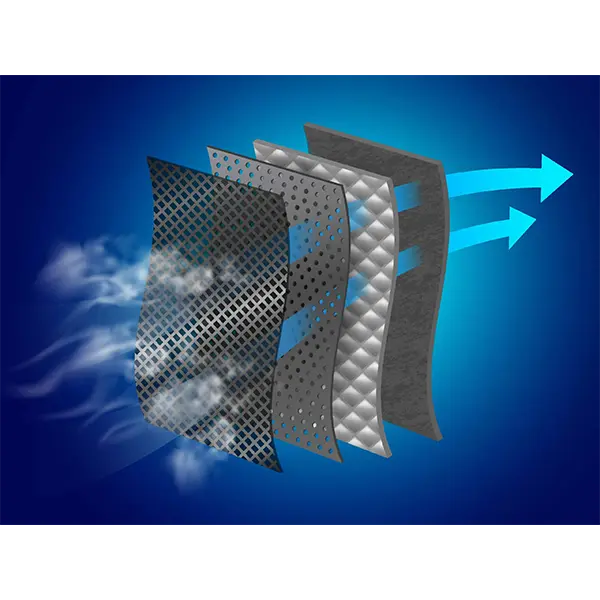

Element Structure

①FPM sealing ring ensures airtightness to achieve a better filtering effect.

②The double-layer support mesh is made of stainless steel to ensure the strength of the air Filter Element. The layered filter design structure ensures the filter element’s filter accuracy and protects the glass fiber during the production process. At the same time, it avoids the damage of the Compressor Air Filter Element due to the rust of the material and the secondary effect of compressed air. Sub-pollution.

③The 96% porosity has a significant ability to hold dust, and the service life can reach 6000-8000 hours. The general pressure difference is 0.17-0.25kg/cm, and the maximum is not more than 0.65kg/cm.

④The end cover is made of PA+GF material, under the pressure of 1.8Mpa. It can withstand 240℃ high temperature without deformation, -20℃ without embrittlement, resist general acid and alkali chemical corrosion, and withstand a harsh compressed air environment.

⑤The high-quality, unique material of the outer layer of the cartridge filter element can condense water and oil and has strong oleophobicity and hydrophobicity, preventing oil or moisture from being brought downstream again and ensuring filtration performance.

| Filtration Grade |  |  |  |  |  |  |  |

| PF | AO | AA | AX | ACS | AR | AAR | |

| Particle removal (ISO12500-3) | 5μm | 1μm | 0.01μm | 0.01μm | – | 1μm | 0.01μm |

| Outlet oil aerosol concentration (ISO12500-1) | 5mg/m³ | 0.6mg/m³ | <0.01mg/m³ | <0.001mg/m³ | <0.004mg/m³ | – | – |

| Filtration performance of Particle (ISO12500-3) | – | 99.999+% | 99.999+% | 99.999+% | 99.999+% | 99.999+% | 99.999+% |

| Filtration performance of oil (ISO12500-1) | 50% | 80+% | 99.9+% | 99.99+% | – | – | – |

| Element spanlife | 6000 hours | 6000 hours | 6000 hours | 6000 hours | 2000-3000 hours | 4000-6000 hours | 4000-6000 hours |

| Filtration Type | Coalescence | Coalescence | Coalescence | Coalescence | Adsorption | Coalescence | Coalescence |

| Airflow direction | From inside to outside | From outside to inside | |||||

AK Series Element Feature

>Material: Sodium borosilicate glass fiber

>Under 1.6Mpa pressure and temperature from 1.5~80ºC, serve life:6000~8000 hours

>Follow ISO8573.1-2010 standard, filtration performance up to 99.99%

| Model Number | L017 | L025 | L030 | L035 | L058 | L068 | L080 | L145 | L220 | L260 | L330 | L360 | L405 | L430 | L620 |

| Flow rate (m³/min) | 1.0 | 1.5 | 1.8 | 2.0 | 2.8 | 3.0 | 4.8 | 7.2 | 12.0 | 14.0 | 16.0 | 19.0 | 22.0 | 28.0 | 37.2 |